New Products

Find Robot Industriel, Robot Machines, Robotics Equipment on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Model No.: RERP004

1.Functional characteristics:

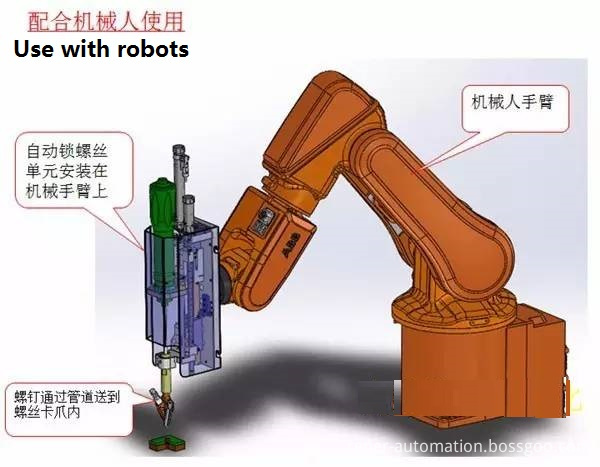

The utility model relates to an automatic locking screw module which can be installed on an automatic machine or a moving robot.

Accurate torque control, including the detection of wear, slippery and leakage lock sensor.

Can be paid at the level, from the bottom to the lock to pay, can be installed at any angle.

The utility model is suitable for the requirement that the screw is vertical or the torsion force is large, and the work station is easy to fatigue.

It can be used with all kinds of machines

Lock screw unit application module

The automatic lock screw unit is used to lock the screws and screws automatic delivery are necessary for automatic screw feed machine.

1. mechanical roller structure, small noise, long life, durable, stable operation.

2. powerful, independent control system, get a command, send the screw immediately and return the feedback signal.

3., can be equipped with 4 channels, you can set the screen after shielding the pipe, replace the product easily.

4., there are many sets of sensors to detect screws, send nails fast, accurate and stable, easy installation and control.

5. industrial design, open structure, even if the material due to poor screw material can also be excluded within a few seconds.

2. Oblique bucket type automatic nailing machine parameters

| The volume | M3X8 standard screw 4000PCS | ||

| | Tooth diameter:M1.0 ~ M6.0mm( Optional) | ||

| Overall length of screw >1.3 screw cap diameter | |||

| Screw length:within 25mm, the shortest should be in line with the previous item | |||

| Screw material: metal or hard nonmetal material | |||

| Efficiency | K101(Equipped with 1 pipes) | 60PCS/ minute | |

| K102(Equipped with 2 pipes) | 30pcs/ minute / pipe(Can be changed to K101 after setting) | ||

| K103(Equipped with 3 pipes) | 20pcs/ minute / pipe(Can be changed to K102 or K101 after setting) | ||

| K104(Equipped with 4 pipes) | 20pcs/ minute / pipe(Can be changed to K102 or K103 after setting) | ||

| Screw delivery mode: | The screw is conveyed with a transparent tube, and the distance can be sent 10 meters farthest | ||

| Power Supply: | AC220V 50HZ DC24V | ||

| Gas source: | pressure 0.5MPa | ||

| Outline size | 430(L)X230(W)X400(H)mm | ||

| weight | K101 ~K104 | 20kg~28kg | |

| LCD function: | Different machine models and programs can be invoked | ||

| Adjust blowing screw time, machine sleep time | |||

| With count function display output. Can be reset, set | |||

| Alarm display for missing material, missing material and card material; | |||

| Screw feed inspection: | Most 4pcs sensor detects screws | ||

| I/O signal | DC 24V Host communication | ||

| The input and output signals can be collected | |||

| Noise: | Average 65dB maximum instant 85dB | ||

| Screw distributor: | Die steel, fine machining, quenching, grinding | ||

| Screw inclined bucket material: | PC transparent material | ||

3. Steps of building full automatic line:

1, The product is immature, there is no stable ready-made process, product life cycle, product annual output

2, If there is automatic line, automatic machine or the same type of production line for reference.

3, Whether all products can automatic feeding, product structure is suitable for automatic assembly, automatic assembly to change the feeding material, modified materials instead of packaging, part of product structure, product assembly a chamfer there, add to the appropriate.

4, Some testing instruments may be manual, be instead of automatic operation.

5, If the production line site has no limit, determine the length of the production line width.

6. The layout structure of the production line is determined as follows: straight line without load type, straight line horizontal carrier backflow type, straight line download with reflux type, multiple turntable direct connection, turntable plum blossom type, right angle type, U form.

7, The production line standard accessories brand determination.

8, Production line vulnerability and spare parts determination.

9, The production line acceptance standards identified.

10, Both sides of the program audit

11, Price determination, contract with the determination of the two sides to determine the follow-up, single order production delivery.

4. About us:

Dongguan Rener Automation Technology Co., Ltd. is a high-tech enterprise engaged in R & D, industrial non-standard machinery and equipment production, sales and service automation.Our products are widely used in automatic production of standard fasteners, hardware accessories, auto parts, electronic parts, electrical appliances, plastic hardware, locks, medical equipment accessories, cosmetics, sanitary products and Other industries. Undertake mobile phone connector, automotive, medical, hardware, wire, all kinds of consumer electronic products, sanitary products and other non-standard automation equipment R & D project development, to undertake a variety of plastic hardware products production line, assembly line, automatic machine manufacturing, design various automation solutions.Effective for the enterprises to solve the problems in high cost, low efficiency and serious quality, recruitment difficulties, labor trouble etc...For all enterprises to save resources, improve efficiency, achieve social harmony and win-win and customer.

Our main products: plastic & Hardware assembling machine, sanitary assembly machine, automatic locking screw machine, spring separating feeder machine, we developed a number of sanitary assembly line has been successfully put into production in the Middle East.

We have experienced technical backbone and a strong engineering team, and provide overseas machine commissioning and overseas training experience and service, make the enterprise production line put into production, we provide technical support and thoughtful pre-sale customer service for customers in the industry field, we will make unremitting efforts to strive for the majority of customer service. Dongguan Rener automation technology limited company's good faith, strength and quality of products recognized by the industry. Welcome friends from all world of life come to visit, guidance and business negotiation

5. Customer Service:

1) Warranty period:1 years (Non-human damage and other factors)

2) Provide logistics, customs service and foreign installation ,commissioning and operator training service for the machine.

2. How many days will you finish installing & commissioning ?

We will finish installation,commissioning and training within 15-25days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary 50USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Pls Note:

Product Categories : Robot Production Line